Information

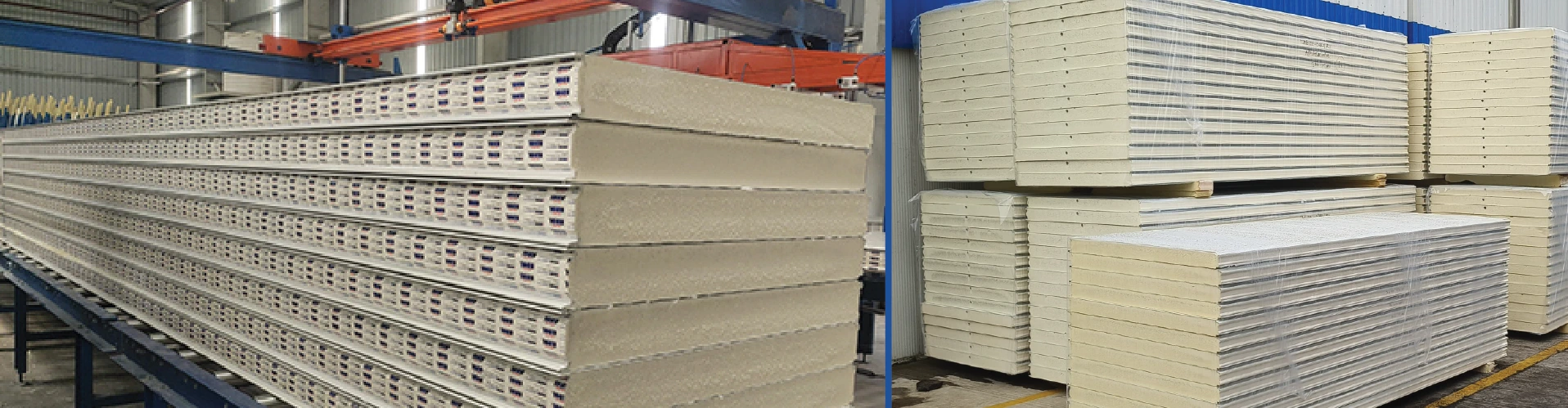

- Design Profile: Insulated PUR & PIR Panels with tongue and groove joints.

- Density: PUR 40 ± 2kg/m³ and PIR 45 ± 2kg/m³

- Steel Type: PPGI, PPGL

- Sheets Profile: Baby Ribs, Micro Ribs, Plain

- Length: Standard length from 2 m to 15 m

- Cover Width: 1000 mm, 1145 mm

- Thickness: 30, 40,50, 60, 80, 100, 120, 150 mm available

Wall PUF Panel

Wall panels are essential elements in modern construction, offering both functional and aesthetic value. They are used across various sectors, including industrial, commercial, and residential projects. These panels provide a seamless solution for insulation, fire resistance, noise reduction, and structural integrity.

Why PUF Wall Panels Are Better Than Other Panels

Polyurethane Foam (PUF) wall panels offer several advantages over other wall panel types, making them a preferred choice in many applications:

- Superior Thermal Insulation:

PUF wall panels provide excellent thermal insulation with low thermal conductivity. This ensures better energy efficiency, making them ideal for cold storages, refrigerated warehouses, and controlled environments like clean rooms. The low U-value of PUF panels ensures that they minimize heat transfer, leading to significant energy savings.

- Lightweight and Easy Installation:

PUF panels are lighter than their Rockwool or EPS counterparts, reducing transportation costs and enabling quicker, easier installation. Their lightweight nature allows for faster construction times, lowering labor costs and project timelines.

- High Structural Strength:

Despite their lightweight composition, PUF wall panels offer high compressive strength, making them suitable for both interior and exterior applications. They can withstand significant external loads and environmental stresses, enhancing the overall durability of the structure.

- Excellent Fire Resistance:

Modern PUF panels are treated with fire retardant chemicals, ensuring they meet required fire safety standards. They offer a balance between insulation and fire protection, particularly important for industries like pharmaceuticals and food processing, where safety and hygiene are paramount.

- Moisture Resistance:

PUF wall panels have low water absorption, offering excellent resistance to moisture and preventing the growth of mold or mildew. This makes them an ideal choice for humid environments, including cold storages and freezers.

- Cost-Effective Solution:

While the initial cost of PUF panels may be slightly higher than some alternatives like EPS panels, their long-term cost benefits make them a more economical solution. The superior insulation properties reduce energy consumption, lowering operational costs over time. The durability and low maintenance needs also contribute to cost savings.

- Environmentally Friendly:

PUF panels are eco-friendly due to their long lifecycle and energy-saving properties. They also have a lower carbon footprint compared to some other insulating materials, aligning with sustainable construction practices.

PUF Properties:

| Properties | Polyurethane Foam(PUR) | Polyisocyanurate Foam(PIR) |

|---|---|---|

| Insulation | CFC & HCFC Free Rigid Polyurethane Foam(PUF) As Per is 12436 Standard | CFC & HCFC Free Rigid Polyisocyanurate Foam(PUF) As Per is 12436 Standard |

| Foam Overall Density | 40 +/-2kg / cu.m | 40 +/-2 kg / cu.m |

| Foam Thermal Conductivity (k-value) at 10o c Mean Temp. | 0.023 W/m k | 0.023nW/m k |

| Compressive Strength @ 10% Deformation | 2.10 Kg/sq.cm | 2.10 Kg/sq.cm |

| Tensile Strength | 2.5 Kg/sq.cm | 2.5 Kg/sq.cm |

| Flextural/Bending Strength | 3.0 Kg/sq.cm | 3.0 Kg/sq.cm |

| Shear Strength | 2.5 Kg/sq.m | 2.5 Kg/sq.m |

| Closed Cell Contents | 90-95% | 90-95% |

| Horizontal Burning Characteristics | 125 mm (Extent of Burn)-Max,Fire Retardent,Self Extinguishing Quality Foam | 25 mm (Extent Of Burn)-Max, Fire Retardent,Self Extinguishing Quality Foam |

| Water Absorption | 0.2% Volume at 100% RH,-Max | 0.2% Volume at 100% RH,-Max |

| Water Vapour Permeability | 0.12 ng/pasm at 88% RH & 380C-Max | 0.12 ng/pasm at 88% RH & 380C-Max |

| Dimensional Stablity at -250c Cold Temp. | +-2% | +-2% |

| Dimensional Stablity at +700c Cold Temp. | +-2% | +-2% |